In our focus to develop the best products for the marine market, we continuously invest to make all of our products even better. In this article we present the difference between flat fins and Vector fins™.

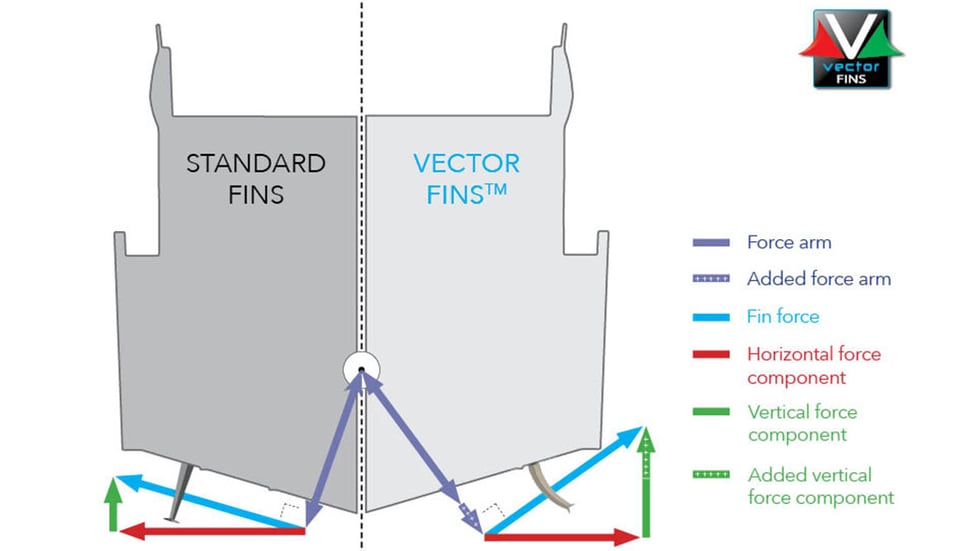

Vector fins™ redirect the force direction

Vector Fins™ simply redirect the force direction/force vectors so that more of the force will benefit roll reduction and less force is wasted on the negative side-effects of yaw and sway that is unfavorable for a boat’s handling and comfort on board.

The vertical concave shape of the fin creates a net force direction, both in cruising and in “at anchor” situations, so the work is more “up/down” instead of side to side or almost horizontal, as flat fins work with forces parallel to the hull angle.

Read more: What are stabilizers and how do they work?

More stabilization per fin size

But there is more. By changing the net force angle, this also increases the leverage arm around the boat’s rolling point, further increasing the physical forces that work on the boat to reduce roll. This provides a lot more roll stabilization per fin size, which means that drag, power consumption, internal space occupation as well as load on the mechanical parts is a lot less than with other fins that can give a similar roll reduction.

Vector fins features

- Up to 50 percent more efficient than flat fins.

- Up to 55 percent less side-effects than flat fins.

- Advanced hydrodynamic fin design.

- 20-50 percent less resistance than other fins, results in virtually no loss of speed and thereby no added fuel consumption.

- The fins are made as a "one shot" vacuum injected vinylester process over pre-shaped core material in a closed mold method.

Read more: How to choose the right stabilizer for your boat

Designed with roving and mat layers to ensure maximum strength and minimum weight. It can even withstand small damages without totally disintegrating afterwards as traditional production methods often allow.